Corporate

Social Responsibility 2022

The most sustainable instrument is one that lasts for a long time.

From the very first day that HEINE was established in 1946, the company’s principles – that are still its firm foundations even today – were clear. We produce German workmanship of the highest quality.

Many of the thousands of medical primary diagnostic instruments we have sold are still working as well today as they were on day one, often even being passed down from one generation to the next. Because we make them with high-quality materials. With precision and perfection. And a healthy helping of IQ and love of craftsmanship. So the durability of our HEINE instruments is now legendary – worldwide.

And if a HEINE instrument needs to be repaired – which is rarely the case – we will repair it. We developed and built it, and we know exactly how to go about fixing it. Very often, the instrument will after a short time be working again like it was on day one. And that’s what our customers appreciate about us. And, let’s not forget, the environment. Although we couldn’t have imagined 76 years ago that conservation of resources would one day become a key driver of all business activities.

Avoid and reduce: 6 examples of our sustainability strategy.

In the following, we would like to use a few examples to illustrate how serious we are about protecting the environment and conserving resources, but also about acting responsibly as a company. If you want to know everything right away, go directly to the CSR (Corporate Social Responsibility) report.

Society

& Prevention.

Everyone is welcome here.

As HEINE is a family-owned business, inclusion is a matter of course for us and it is only natural that we shoulder our social responsibility to offer people with disabilities a professional future. In 2022, we employed 27 staff with severe disabilities in the company.

Skin colour, language, religion, origin and age do not matter to us. Employees from 24 countries work at HEINE.

© Christiane Paschke

We are helping to help.

We support this project by making donations in kind to help train medical staff to identify childhood eye diseases at an early stage. This project in Kenya has been running since 2007, with the goal of providing early detection and timely treatment of childhood eye diseases.

Early diagnosis and treatment can prevent blindness in many cases.

There's more to it than that. HEINE supports many other projects and aid organisations.

Instruments

& Innovations.

Now you can use fridges to look into children’s ears.

HEINE was first again! In close cooperation with our specialist for high-quality plastics, HEINE is the first manufacturer to succeed in implementing an upcycling process for ear tips: discarded refrigerators are turned into accessories for a medical device. This was a challenging task, as particularly strict regulations apply to products that come in direct contact with patients during an examination.

We use plastic from discarded refrigerators. And by recycling these refrigerators in a controlled manner, we save the environment 1,996 tonnes of CO2 equivalents1 per year. This corresponds to 62 million kilometres of rail travel per person, which equates to travelling about 1,400 times around the world. What’s more, we now manufacture the EcoTips on a new machine that requires only half the electricity. Green electricity, of course – generated from hydropower! And finally, we pack the EcoTips in unbleached cardboard, which we also print with just one single colour instead of four.

1 The term ‘CO2 equivalent’ is a unit of measurement that is used to measure the impact that various greenhouse gases have on the climate. Detailed explanation in our CSR Report 2022.

Environment

& Sustainability.

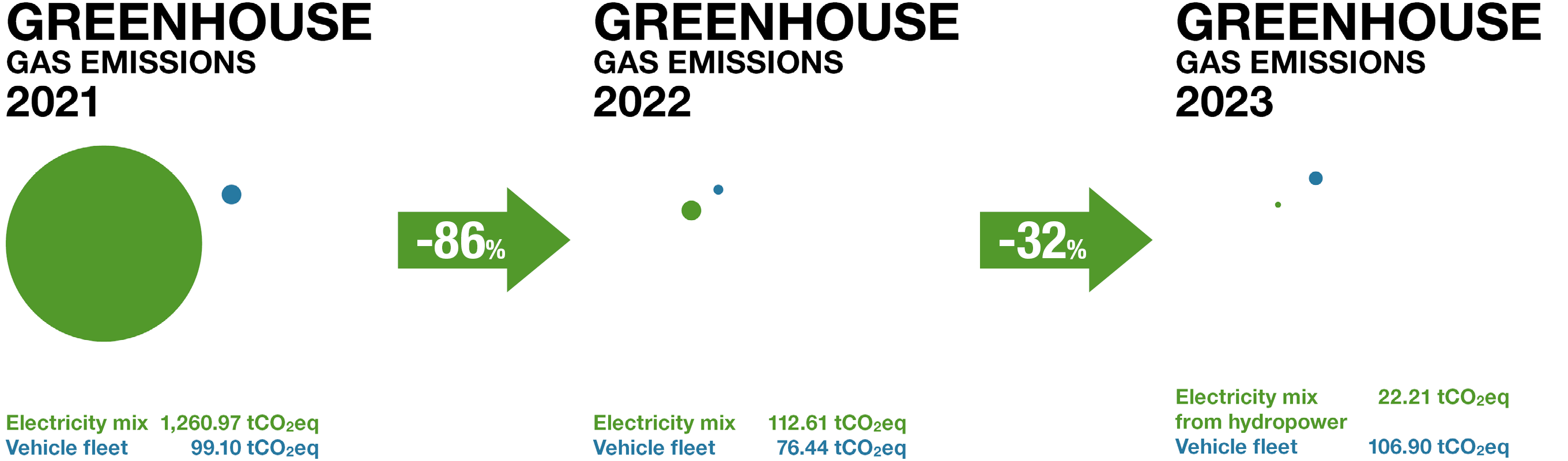

How to save 86% CO2 with a change of address.

In June 2020 – in the middle of the coronavirus pandemic – we all moved to our new building in Gilching (west of Munich). One major goal of this undertaking was to avoid the use of fossil fuels at our new site. Even if moving was more expensive than taking a conventional route!

That’s why, for example, the entire building is cooled in summer by a groundwater-powered heat pump and heated in winter by recovering energy from the waste heat that our machines generate. Almost half of our property is green, as is the roof. And that, of course, has drastically changed our energy footprint at our head office! Because, now, we use neither natural gas nor heating oil (i.e. no fossil fuels) for our production operations at the Gilching site. We have also been sourcing local green electricity since 2022. Thus we reduced greenhouse gas emissions at the Gilching site and at our branch office in Weimar by 86% between 2021 and 2022!

Birch trees would buy HEINE.

Bees, beavers and bearded carnations too.

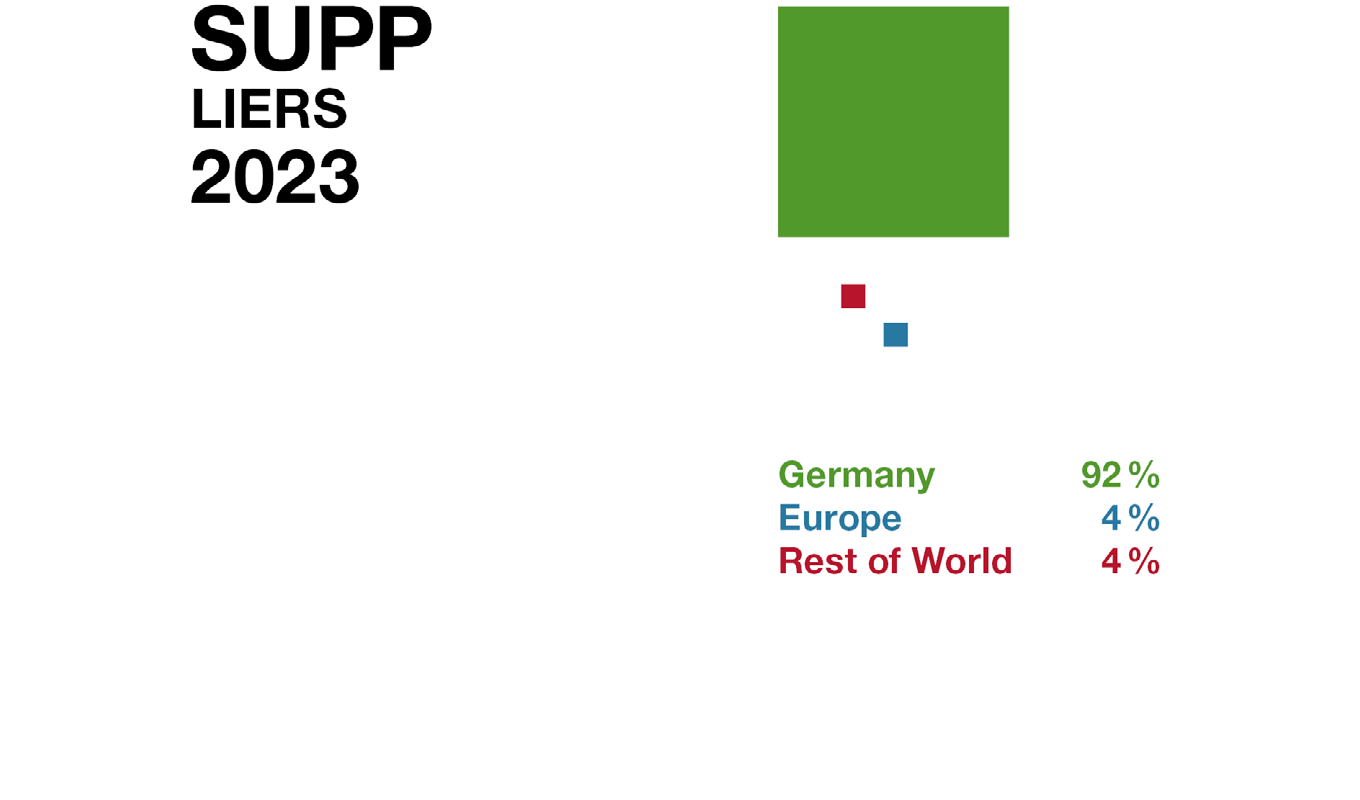

All HEINE instruments – otoscopes, laryngoscopes, loupes, lights, ophthalmoscopes, dermatoscopes, sphygmomanometers and more – are fully manufactured in Germany. And we will continue with our local manufacturing efforts in future too. Our instruments are sold worldwide, so in that sense we are completely cosmopolitan. But we are the exact opposite when it comes to our purchasing activities and selecting our suppliers.

Just over 90% of vendor parts come from Germany. Indeed, 45% come from Bavaria and southern Germany. We even develop and manufacture the control electronics for our lithium-ion batteries and LEDHQ ourselves on site. This has the welcome side benefit that we save ourselves transport costs and cut back on the amount of harmful emissions released into the environment. And this pleases flora and fauna.

Even our waste is not wasted.

The area on our premises where we separate metals and plastics looks like a small recycling yard. Because we separate materials by type as much as possible to keep the unrecyclable materials rate as close to zero as possible. And it actually does go that low at HEINE.

The basic principle in waste legislation is the circular economy. If possible, the raw materials used should circulate in material cycles to reduce the use of natural resources and prevent waste to the greatest extent possible. We believe that material recovery and recycling take top priority over disposal. By registering in Germany with the legally required bodies and commissioning certified take-back systems, we as a manufacturer are meeting our product responsibility obligations and are helping to conserve natural resources. That way, we are ensuring that our products – including the packaging materials – are disposed of in an environmentally compatible way. We dispose of all the waste materials generated in the company in an environmentally friendly manner in line with official requirements.